- We are a manufacturer of oil press equipment and grain and oil processing equipment.

- Email:2334065214@qq.com

Palm kernel oil, as an important source of edible oils and industrial raw materials worldwide, and the evolution of its extraction process reflects the epitome of the process of agro-industrialization. From the traditional hand-pressing in West Africa to the modern mechanized assembly line, the two methods show significant differences in terms of raw material handling, oil production efficiency, oil quality and environmental impact. Through comparative analysis, this paper reveals the core contradictions and development logic of traditional process and mechanized production.

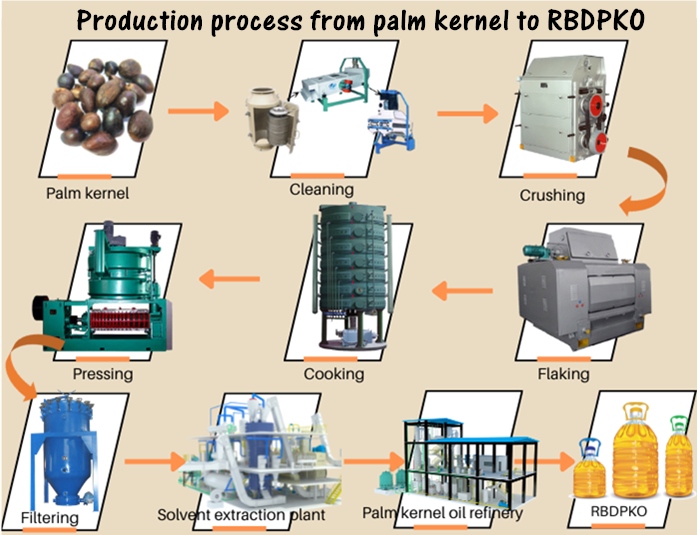

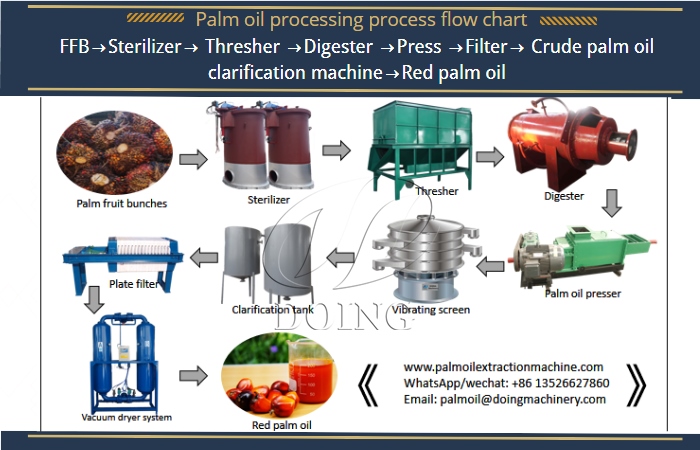

First, raw material processing: from manual sorting to intelligent grading

Traditional palm kernel oil extraction relies on manual operation, the kernel needs to go through the polishing drum to remove surface impurities, and then through the nucleus grading sieve to screen the difference in particle size. The shelling process relies on the kernel-shell separator wind selection technology, but limited by the efficiency of manual sorting, the impurity mixing rate is as high as 5% -8%. Mechanized production introduces optical color sorter and X-ray foreign object detection system, which can accurately remove moldy kernels and metal impurities, and the impurity mixing rate is reduced to less than 0.1%. For example, the intelligent grading system manufactured by Henan Guorui reduces the kernel breakage rate from 12% in the traditional process to 2.3% through AI image recognition technology.

Second, pressing technology: from lever extrusion to double-screw pressurization

Traditional pressing adopts lever-type wooden presses, driven by manpower or animal power, with a single pressing cycle of 4-6 hours and an oil yield of only 18%-22%. The core defect lies in the uneven pressure distribution, resulting in less than 60% of kernel cell breakage. The modern mechanized production adopts double screw oil press, equipped with frequency conversion speed control system and pressure feedback device, which can realize 120MPa continuous high pressure, and the kernel cell crushing rate is increased to more than 95%. Take a factory in Malaysia as an example, its production line has a single-day processing capacity of 200 tons, and the oil yield is stable at 24%-26%, which is 35% higher than the traditional process.

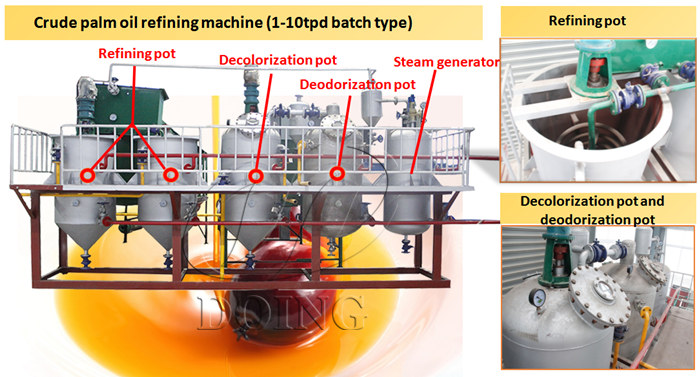

Refining process: from empirical control to data-driven

Traditional refining relies on “fire” and “feel”, and the acid refining process needs to manually judge the amount of phosphoric acid to be added, resulting in fluctuations in the removal of free fatty acids in the range of 70%-85%. Alkaline refining process is easy to produce soap foot residue, so that the loss rate of neutral oil as high as 3% -5%. The mechanized production adopts PLC control system and adjusts the phosphoric acid concentration in real time through online acid value detector, and the removal rate of free fatty acid is stable at over 98%. The decolorization link introduces activated white clay adsorption model, which can automatically match the adsorption parameters according to the type of pigment and increase the decolorization efficiency by 40%. For example, an international grain and oil group adopts physical refining technology to control the loss rate of neutral oil within 1.2%, which is 70% lower than the traditional process.

Fourth, the environment and cost: from resource consumption to green manufacturing

The traditional process requires 0.8 cubic meters of wood and 15 tons of water per ton of palm kernel oil production, and produces wastewater containing COD (Chemical Oxygen Demand) as high as 8,000mg/L. The mechanized production through the heat recovery system, the utilization rate of steam from 65% to 92%, and wastewater can reach the national level of emission standards after treatment by membrane bioreactors. In terms of cost, the labor cost of traditional process accounts for 35%, while the mechanized production line reduces the energy consumption per unit of product by 40% and the comprehensive cost by 22% through automation.

Quality and safety: from sensory evaluation to standard traceability

The quality of traditional oil products relies on the experience judgment of “old craftsmen”, with acid price fluctuating in the range of 0.5-2.0mgKOH/g, and peroxide value exceeding the standard rate of 18%. The mechanized production establishes HACCP system, the key control point realizes 100% data recording, the acid price fluctuation is controlled within ±0.1mgKOH/g, and the peroxide value is stabilized at below 0.05mgKOH/g. The blockchain traceability system can trace the origin of raw materials, processing parameters and inspection reports of each batch, which improves the efficiency of product recall by 90%.

The leap from traditional to mechanized is not only a revolution in efficiency and quality, but also a profound reflection on the way human beings use natural resources. When mechanized production shows overwhelming advantages in guaranteeing food safety and reducing environmental load, the inheritance value of traditional crafts is more reflected in cultural memory and craft innovation. The palm kernel oil industry in the future will build a more efficient, greener and smarter industrial ecology on the cornerstone of mechanization.

gao

Henan Zhongrui Grain is a high-tech enterprise specializing in the research, development, manufacture and sales of oil press equipment, and has been deeply engaged in the field of oil processing for more than ten years. The company integrates design, production and testing, and its products cover screw oil press, hydraulic oil press, automatic refining production line, etc., which are suitable for rapeseed, peanut, soybean, sesame and other oilseeds, and help customers to realize efficient, energy-saving and environmentally friendly oil and grease production.

Contact Us

Product Center

menu

Recommended

© 2025. All Rights Reserved. 豫ICP备19039166号 Theme By XinTheme