- We are a manufacturer of oil press equipment and grain and oil processing equipment.

- Email:2334065214@qq.com

As one of the world’s important palm oil producers, Nigeria’s palm oil processing industry has shown a dual trend of equipment upgrading and capacity expansion in recent years due to the surge in domestic demand and the linkage effect of the international market. This article combines the latest market data to analyze the market pattern of palm oil processing machines in Nigeria from the dimensions of equipment type, price range, technology trend and industry challenges.

I. Core Equipment Types and Capacity Distribution

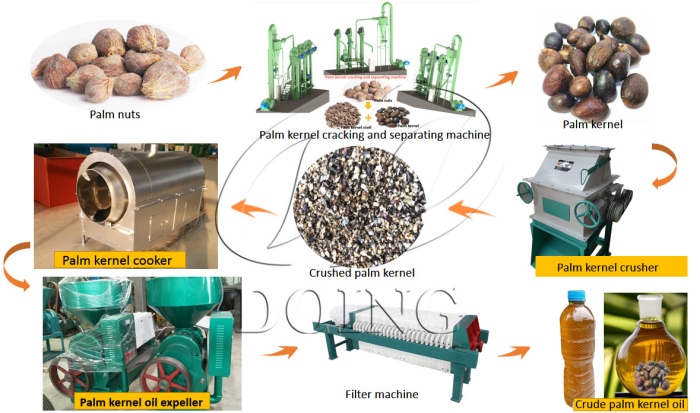

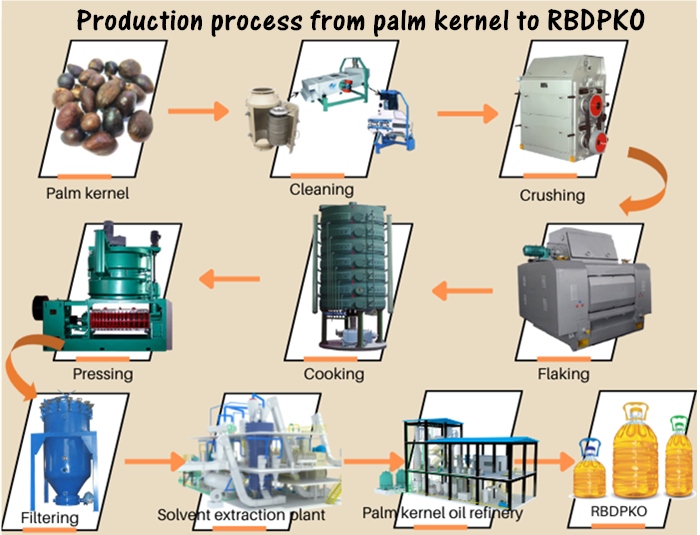

Nigerian palm oil processing equipment is mainly divided into three modules, namely pressing, refining and fractionation, covering the whole process from fresh fruits to finished oil products

Pressing equipment

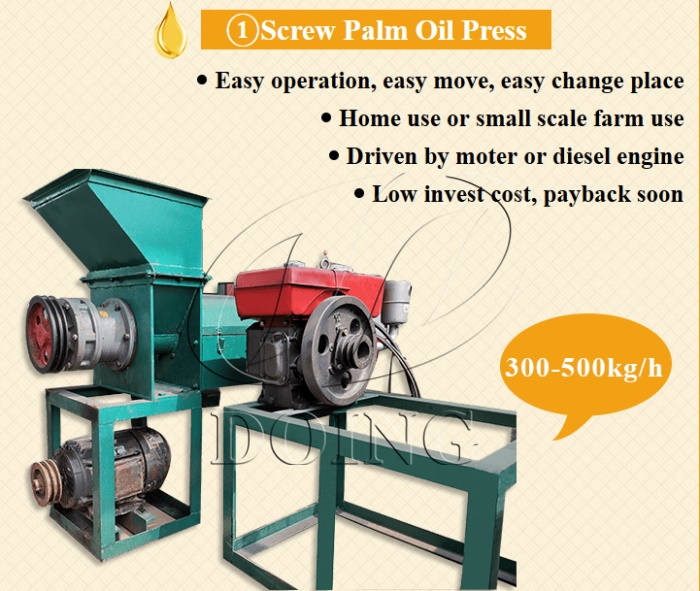

Small double-screw oil press: daily processing capacity of 0.5-2 tons, applicable to family workshops or small cooperatives, with a price of about 100,000-300,000 yuan (e.g., Henan Forester Intelligent Technology’s basic type production line).

Medium-sized continuous oil press line: daily processing capacity of 1-5 tons, equipped with automated fresh fruit disinfection, shelling, pressing system, price of about 1 million – 2 million yuan (such as Zhengzhou Zhiqian Machinery 50 tons / day full continuous equipment).

Large-scale industrial oil pressing plant: the daily processing capacity is more than 50 tons, integrating steam treatment, screw pressing and gross oil storage, and the investment of a single set of equipment is more than RMB 5 million (e.g. Henan Guorui Oil & Grease’s 1,000 tons/day project for Akwa Ibom State, Nigeria).

Refining equipment

Intermittent refining tower: It is suitable for small and medium-sized factories to improve the quality of fats and oils through acid and alkali neutralization, decolorization and deodorization processes, with a price of about RMB 500,000-1,500,000 (e.g. Gongyi Wanlong Machinery’s 10t/d refiner).

Full continuous refining line: adopting molecular distillation technology, it can produce zero trans fatty acid high-end oils and fats, the price is over RMB 3 million (e.g. Zhejiang Zhonghuan Intelligent Machinery 500 tons/day fractionation equipment).

Auxiliary equipment

Palm kernel shell separator: the efficiency of the wet separation equipment is up to 98%, the price is about 200,000-500,000 RMB (e.g. Guorui Oils & Fats in Sierra Leone project).

Steam boiler and power distribution system: power 50-500kW, price accounts for 15%-20% of the overall investment.

II. Analysis of Price Driving Factors

Raw Material Cost Fluctuation

International palm oil price is expected to remain at RM4,000-5,000/tonne (approx. US$906-1,133/tonne) in 2025 due to stagnant production in the main producing countries, an increase of 4.5% from 2024. Equipment manufacturers have raised prices of core components such as steel and motors by 8%-12% in response to cost pressures.

Technology Upgrade Premium

Automated control systems (e.g. PLC remote monitoring) can result in a 20-30% premium for equipment, but can reduce labor costs by 30%.

Energy-saving heat exchangers can reduce steam consumption by 40% and shorten the payback period to 2 years.

Import Tariffs and Logistics Costs

Nigeria imposes 5%-20% tariffs on imported machinery, which, overlaid with transportation costs from Lagos port to inland (about $0.5/ton-km), results in imported equipment prices that are 15%-25% higher than in China itself.

Regional Market Differences and Typical Cases

Southern Producing Region (Akwa Ibom State)

Large-scale plantations are dominant, and equipment procurement presents the characteristics of “scale + intelligence”. For example, in 2025, a local enterprise introduced a 1,000-t/d fully continuous production line, integrating German centrifuges and domestic screw presses, with a total investment of 8 million U.S. dollars, and the cost per unit of production capacity is 40% lower than that of traditional equipment.

Northern Emerging Producing Region (Kaduna State)

Small and medium-sized workshops account for more than 70% of the total, preferring cost-effective solutions. For example, a cooperative purchased a 5-ton/day double screw oil press with a domestic refining tower, with a total investment of less than RMB 2 million, and achieved a payback in 18 months through the model of “direct pressing of fresh fruits + bulk oil sales”.

Policy dividend windowThe Central Bank of Nigeria (CBN) launched the “Palm Oil Value Chain Financing Program”, which provides 5-year low-interest loans for equipment purchases (interest rate of 9% per annum), boosting the number of small and medium-sized processing mills by 15% per annum.

Challenges and Strategies

Unstable power supply

The national grid coverage of Nigeria is less than 60%, and processing mills need to provide their own diesel generators, which leads to an increase of 25%-30% in operating costs. Solutions include:

Purchase dual power system equipment (grid + diesel), such as the “Intelligent Switching Oil Press” launched by Guorui Oils & Fats.

Apply for CBN solar subsidies and build a PV plant on the factory site.

Shortage of skilled personnel

The average daily wage of local skilled operators is only 5,000 naira (about $6), but the shortage of senior technicians is 60%. Enterprises generally adopt the “China training + localization” mode, such as Zhengzhou Zhiqian Machinery set up a technical service center in Lagos, providing three months of free operation and maintenance training.

Underutilization of by-products

The comprehensive utilization rate of palm kernel shells, empty fruit bunches and other wastes is less than 30%, while Chinese equipment manufacturers have developed value-added solutions such as biomass pellet machines and organic fertilizer production lines. For example, Zhejiang Zhonghuan Intelligent Machinery’s “oil extraction – shell pellet co-production” equipment can increase the comprehensive income of the plant by 20%.

V. Future Trends

Rise of Modularized Equipment

Demand for detachable container processing stations (with integrated pressing, refining and oil storage functions) is growing in response to Nigeria’s weak rural power grids, with the price of a single set of equipment ranging from 800,000 to 1.5 million yuan, and the installation cycle shortened to seven days.

Penetration of digital management system

Intelligent oil presses equipped with IoT sensors to monitor parameters such as oil yield and equipment temperature in real time are expected to exceed 30% market share by 2026.

Accelerated localized production

Chinese equipment vendors are cooperating with Nigerian Dangote Group and other enterprises to build factories, aiming to achieve 60% localized production of parts, and equipment prices are expected to drop by 15%-20% in the future.

The Nigerian palm oil processing equipment market is in a critical period of technology iteration and scale expansion. For investors, it is necessary to balance capacity planning and cost control, and prioritize the selection of suppliers with “energy-saving + intelligent + after-sales” integrated solutions to cope with power fluctuations, talent shortages and other practical challenges. With the continuous force of CBN policy and the deepening of China-Nepal technical cooperation, 2025-2030 may become the golden period of industry development.

gao

Henan Zhongrui Grain is a high-tech enterprise specializing in the research, development, manufacture and sales of oil press equipment, and has been deeply engaged in the field of oil processing for more than ten years. The company integrates design, production and testing, and its products cover screw oil press, hydraulic oil press, automatic refining production line, etc., which are suitable for rapeseed, peanut, soybean, sesame and other oilseeds, and help customers to realize efficient, energy-saving and environmentally friendly oil and grease production.

Contact Us

Product Center

menu

Recommended

© 2025. All Rights Reserved. 豫ICP备19039166号 Theme By XinTheme