- We are a manufacturer of oil press equipment and grain and oil processing equipment.

- Email:2334065214@qq.com

Palm kernel oil, as an important global industrial oil and fat raw material, the investment cost of its processing equipment is affected by multiple factors. Combined with the latest market data and industry dynamics in 2025, this article will systematically analyze the cost composition of palm kernel oil press machine from the dimensions of equipment type, process configuration, market supply and demand.

I. Equipment type and cost range

The cost of palm kernel oil press is directly related to its processing scale, automation degree and process complexity. According to the quotations of the mainstream equipment suppliers in the industry, the current market is mainly divided into the following three categories:

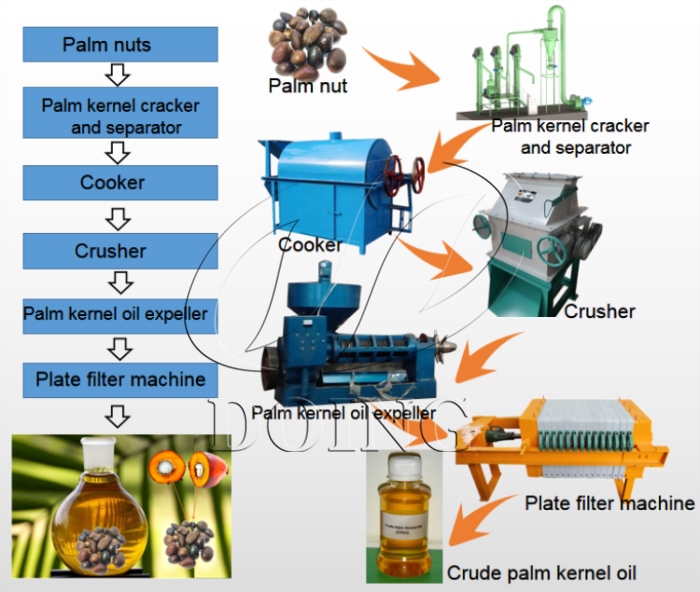

Small-scale equipment: applicable to start-up enterprises or family workshops with a daily processing capacity of 0.5-2 tons, with the basic configuration including fruit removing machine, press, plate and frame filter, etc., and with a cost of about 150,000-500,000 RMB. For example, the 500kg/h double screw oil press production line provided by Henan Zhongrui Cereals and Oils Machinery costs about 250,000 RMB, which can meet the demand of small-scale processing.

Medium-sized equipment: daily processing capacity of 1-5 tons, suitable for medium-sized processing plants, configured with refining equipment such as killing fermentation tanks, pounding tanks, rotary vibrating screen, etc., costing about RMB 500,000-1,500,000 yuan. For example, a company configured 10 tons / hour standard production line, including de-fruiting, pressing, refining the whole process, the total cost of about 1.2 million yuan.

Large-scale equipment: the daily processing capacity of more than 5 tons, suitable for large-scale chemical plants, the use of continuous pre-pressing leaching process, the cost of the equipment can be up to 1.5 million – 3 million yuan. This type of equipment is usually integrated with automation control system, which can realize 24-hour continuous production.

Second, the core elements of the cost composition

Equipment configuration differences

Basic: only includes pressing and filtering, suitable for rough processing, low cost.

Refining type: increase the refining process such as deacidification, decolorization, deodorization, etc., and increase the cost by 30%-50%. For example, in 2025, an enterprise in East China purchased 5 tons/day refining equipment, the offer is about 450,000 yuan.

Customization: Depending on the characteristics of raw materials (e.g. high hardness of palm kernel requires special shelling design) or process requirements (e.g. high purity oleic acid extraction), the cost may be doubled.

Degree of automation

Automated production lines can reduce labor costs, but the initial investment increases. For example, the introduction of a fully automated control system in a medium-sized factory increases equipment costs by 20%, but reduces labor costs by 40%.

Supporting facilities and installation

Supporting facilities such as conveyor belts, storage tanks and environmental protection equipment account for about 15-20% of the total equipment cost. In addition, the cost of installation and commissioning can reach 50,000-200,000 yuan due to regional differences.

III. Impact of market supply and demand on costs

Raw material price fluctuations

In the first half of 2025, palm kernel oil prices rose to a nearly three-year high, mainly due to production cuts in the production area (such as the decline in the production of palm fruits due to climate anomalies in Southeast Asia) and the supply of alternative fats and oils (such as coconut oil) is tight. Rising raw material costs directly pushed up the return on investment cycle of oil presses, for example, a company originally planned to pay back the capital in 2 years, due to raw material price increases extended to 3 years.

Technology Iteration and Competition

Domestic manufacturers reduce equipment costs by optimizing processes (e.g., low-temperature pressing technology to reduce residual oil rate). For example, the residual oil rate of a new double-screw oil press was reduced from 8% to 6%, and the price of the equipment only increased by 10%.

Policies and environmental requirements

Environmental regulations are tightening, some areas require the addition of exhaust gas treatment equipment, the cost increased by 50,000-100,000 yuan.

Fourth, the investment decision-making suggestions

Scale appropriate: select the capacity according to market demand, avoid excessive investment. For example, in 2025, the annual domestic consumption of palm kernel oil is about 1.2 million tons, small and medium-sized equipment can cover 60% market share.

Technology Priority: Prioritize equipment with low residual oil rate and low energy consumption, with significant long-term cost advantage.

Risk control: pay attention to the fluctuation of raw material prices (such as palm kernel futures market) and policy changes, and reserve 10%-15% contingency funds.

V. Future Trend Outlook

With the expansion of global downstream industries such as fatty alcohols and hydrogenated oils, the demand for palm kernel oil is expected to continue to grow. Equipment suppliers are accelerating the research and development of intelligent and energy-saving oil presses, for example, the AI regulation system launched by a company can reduce energy consumption by 15%. Meanwhile, the Southeast Asian production expansion program may ease the raw material tension, but need to be vigilant about the long-term impact of climate change on production.

The cost of palm kernel oil press is affected by multiple factors intertwined, investors need to consider the performance of equipment, market supply and demand and policy environment. In the context of the 2025 market, rational planning of production capacity and investment scale, and selecting technologically leading equipment suppliers will be the key to realizing long-term gains.

gao

Henan Zhongrui Grain is a high-tech enterprise specializing in the research, development, manufacture and sales of oil press equipment, and has been deeply engaged in the field of oil processing for more than ten years. The company integrates design, production and testing, and its products cover screw oil press, hydraulic oil press, automatic refining production line, etc., which are suitable for rapeseed, peanut, soybean, sesame and other oilseeds, and help customers to realize efficient, energy-saving and environmentally friendly oil and grease production.

相关推荐

Contact Us

Product Center

menu

Recommended

© 2025. All Rights Reserved. 豫ICP备19039166号 Theme By XinTheme