- We are a manufacturer of oil press equipment and grain and oil processing equipment.

- Email:2334065214@qq.com

Palm kernel oil, as one of the world’s important vegetable fats and oils, its extraction process combines physical machinery and chemical refining technology, forming a complete set of industrialized processes. This article is based on modern palm kernel oil production practices, systematic combing of its core process links and technical points.

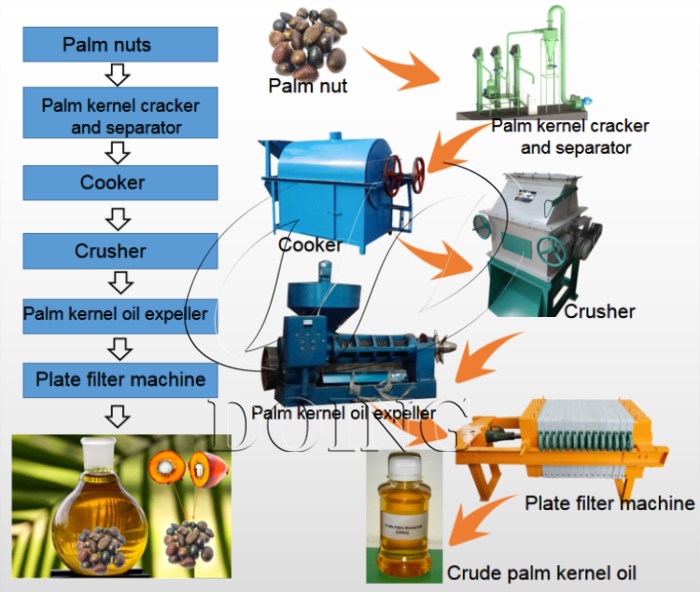

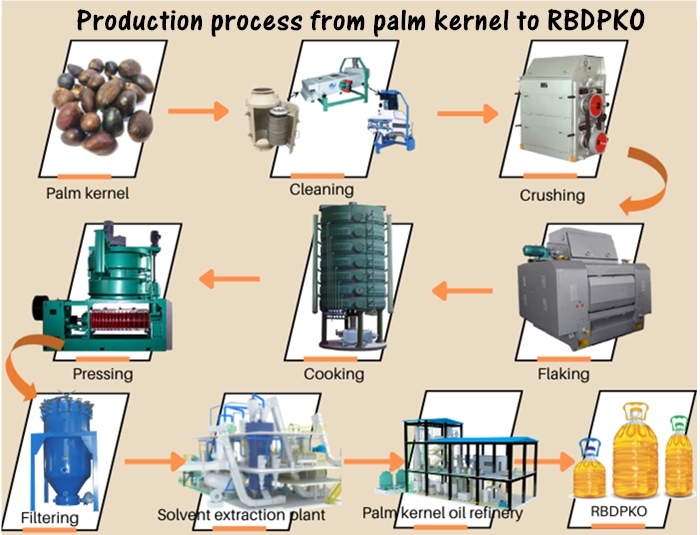

First, raw material pretreatment: from kernel to pure kernel

The extraction of palm kernel oil begins with the palm kernel, which is a by-product of palm fruit pressing. The link through the multi-stage separation equipment to achieve complete separation of fiber and kernel:

Fiber-Kernel Separation: Vibrating screen and airflow sorting technology are used to separate the fiber material from the palm kernel after pressing. The fiber material can be used as biomass fuel after drying, while the kernel material enters the grading system.

Kernel grading: The kernels are graded according to diameter (usually divided into large kernels ≥15mm and small kernels <15mm) using tumbler screen or vibrating screen to ensure the efficiency of subsequent shelling.

Separation of kernels and shells: A toothed roller shelling machine is used to separate kernels and shells through mechanical extrusion and shear force. The separated kernel should be further purified by air-selecting column to remove the residual shell debris.

Second, kernel processing: the synergistic effect of crushing and stir-frying

Pure kernel needs to be physically modified to improve the oil yield:

Crushing process: adopt roller crusher to crush kernel to particle size 2-4mm, increase surface area and oil mobility.

Steam frying and tempering: High temperature and high humidity treatment (temperature 110-120℃, humidity 8-10%) in the roller fryer to soften the kernel and adjust the moisture content to 6-8% to create the best conditions for pressing.

Third, oil extraction by pressing: the core technology of physical extrusion

Modern palm kernel oil pressing adopts double screw oil press, and its working principle is as follows:

Progressive extrusion: the diameter of the press screw decreases gradually from the feeding end to the discharging end, with the pressure gradient of the press chamber (up to 60MPa), to realize the continuous extrusion of oil and grease.

Oil residue separation: the pressed gross oil contains 15-20% solids, which needs to be processed by vibrating screen and centrifuge, so that the oil residue separation rate reaches more than 98%.

Utilization of by-products: press cake (containing 5-8% oil) can be further extracted through solvent leaching residual oil, or as animal feed ingredients.

Fourth, gross oil refining: chemical engineering of four-stage degumming

Palm kernel gross oil needs to be refined to improve its quality:

Degumming and deacidification: add phosphoric acid (0.05-0.1%) to hydrate the phospholipids, and then neutralize the free fatty acids with NaOH (dosage of 1.2-1.3 times the content of free fatty acids) to generate the soap foot after centrifugal separation.

Decolorization process: under the condition of 90-100℃ and 99kPa vacuum, add activated white clay (dosage of 2-3%) to adsorb the pigment and trace metal, and separate the waste white clay by plate and frame filter.

Deodorization: Use three-stage steam injection pump to maintain the vacuum degree of 400-666Pa, and pass direct steam at 185℃ to remove free fatty acids and volatile odor substances.

V. Fractionation and modification: to meet diversified needs

Palm kernel oil after refining can be adjusted to melting point characteristics by fractionation technology:

Dry fractionation: control the crystallization temperature (20-25 ℃) and cooling rate (0.5-1 ℃ / h), separation of high melting point hard fat (melting point 44-52 ℃) and low melting point soft fat (melting point 24-33 ℃).

Hydrogenation modification: Under the action of nickel catalyst, partially hydrogenated soft fat can enhance oxidation stability and be used for shortening or margarine production.

VI. Quality Control and Environmental Protection Measures

The modern production line is equipped with online inspection system to monitor the acid value (≤0.2mgKOH/g), peroxide value (≤5meq/kg) and other indicators in real time. Production wastewater is discharged after anaerobic- aerobic biological treatment to meet the standard, while waste residue is incinerated to generate electricity for energy recovery.

The continuous optimization of palm kernel oil extraction process not only improves the oil yield and quality, but also promotes the green transformation of palm industry chain. From raw material pretreatment to refining and extraction, the technological breakthroughs in each step highlight the precision and efficiency of modern oil and grease engineering.

gao

Henan Zhongrui Grain is a high-tech enterprise specializing in the research, development, manufacture and sales of oil press equipment, and has been deeply engaged in the field of oil processing for more than ten years. The company integrates design, production and testing, and its products cover screw oil press, hydraulic oil press, automatic refining production line, etc., which are suitable for rapeseed, peanut, soybean, sesame and other oilseeds, and help customers to realize efficient, energy-saving and environmentally friendly oil and grease production.

Contact Us

Product Center

menu

Recommended

© 2025. All Rights Reserved. 豫ICP备19039166号 Theme By XinTheme