- We are a manufacturer of oil press equipment and grain and oil processing equipment.

- Email:2334065214@qq.com

In the edible oil market, palm oil occupies an important position with its advantages of high yield, low cost and stable performance. Numerous palm oil mills around the world operate day and night to produce a steady stream of palm oil to meet the needs of food, chemical and other industries. However, in the process of palm oil production, the production of waste is inevitable, and these wastes, if not handled properly, will pose a serious threat to the environment and ecology. So, what kind of wastes are produced by palm oil mills? And how to properly handle it?

First, the generation of palm oil mill waste

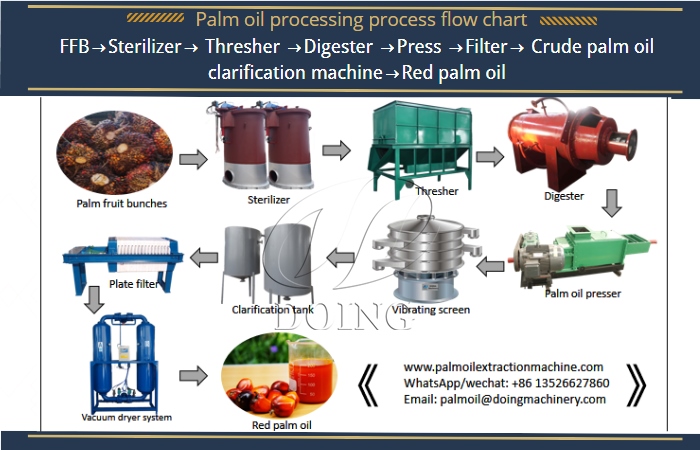

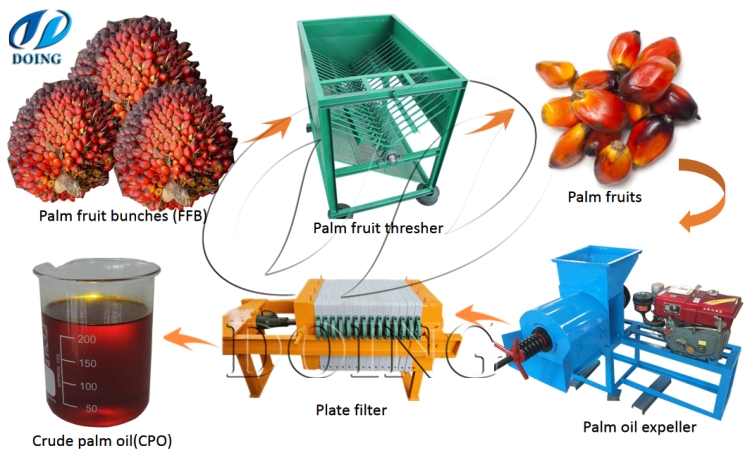

Palm oil production process is complex, from the harvesting of oil palm fruits to the final refining of palm oil, each link may produce waste.

In the pressing of oil palm fruits, a large amount of pressing waste will be generated, mainly including palm fruit fiber and palm kernel shell. Palm fruit fiber is tough and is the fibrous tissue between the pulp and kernel of the oil palm fruit; palm kernel shell is the hard shell that covers the palm kernel. These waste residues are huge in size, and if they are piled up randomly, they not only occupy a lot of land, but also easily breed mosquitoes and spread diseases.

The palm oil after pressing contains impurities, which need to be refined. The refining process produces wastewater, known as palm oil mill effluent (POME). This wastewater is rich in organic matter, suspended matter, oil and grease, and acid, and has extremely high chemical oxygen demand (COD) and biochemical oxygen demand (BOD), which, if discharged directly into natural water bodies, will lead to eutrophication of the water body, depleting the water’s dissolved oxygen and causing aquatic organisms, such as fish, to die due to a lack of oxygen, which will seriously damage the water ecosystem.

In addition, during the production, storage and transportation of palm oil, some waste packaging materials, such as plastic drums and woven bags, may be generated. These waste packaging materials, if not effectively recycled and disposed of, can become a source of solid waste pollution, causing adverse effects on the soil and landscape.

Second, the hazards of palm oil mill waste

The impact of palm oil mill waste on the environment is multifaceted. A large accumulation of pressing waste residue decomposes slowly under natural conditions, releasing greenhouse gases such as methane and exacerbating global warming. At the same time, the organic matter in the waste residue produces foul-smelling gases during decomposition, affecting the quality of life of the surrounding residents.

The high organic content of palm oil mill wastewater makes it a serious source of pollution. When wastewater is discharged into rivers and lakes, it can lead to deterioration of water quality and affect the availability of water resources. Long-term contaminated water bodies may also pose a potential threat to human health through transmission through the food chain. For example, harmful substances in water bodies may accumulate in aquatic organisms such as fish, and human consumption of these contaminated aquatic products may cause various diseases.

Waste packaging materials, if discarded haphazardly in the natural environment, are difficult to degrade and will persist in the soil for a long period of time, affecting the permeability and water permeability of the soil, impeding the growth of plant roots and reducing soil fertility. Moreover, microplastics formed when plastic packaging materials are broken in the environment may also enter the ecosystem and cause harm to organisms.

III. Treatment of Palm Oil Mill Waste

Utilization of Pressing Waste

Pressing waste has a high energy value and can be utilized as a resource in a number of ways. One common method is to dry palm fruit fibers and palm kernel shells and treat them as biomass fuel for power or heat generation. Many palm oil mills have already established their own biomass power plants to convert the waste residue into electricity, which not only meets the mill’s own electricity needs, but also transmits excess electricity to the grid for sustainable energy use.

In addition, the pressed waste residue can also be processed into pellet fuel, which has high combustion efficiency and low pollution, and can be used as a substitute for traditional fossil fuels, widely used in industrial boilers, civil heating and other fields. At the same time, cellulose and other components in the waste residue can also be used for the production of bio-based materials, such as bioplastics, paper, etc., to provide raw material support for the development of environmental protection industry.

Treatment of Wastewater

Aiming at the high pollution characteristics of palm oil mill wastewater, it is necessary to adopt a comprehensive treatment method. First, the larger suspended matter and impurities in the wastewater are removed by physical treatment processes, such as grating and sedimentation. Then, biological treatment techniques, such as anaerobic digestion and aerobic biological treatment, are utilized to degrade the organic matter in the wastewater. During anaerobic digestion, microorganisms decompose organic matter into gases such as methane and carbon dioxide, and methane can be collected and utilized as energy; aerobic biological treatment further removes organic matter and pollutants such as ammonia and nitrogen from wastewater, so that the wastewater meets the discharge standards.

In recent years, some advanced treatment technologies, such as membrane bioreactor (MBR), artificial wetland, etc., have been gradually applied to the treatment of palm oil mill wastewater; MBR technology combines the advantages of membrane separation and biological treatment, with high treatment efficiency and good effluent quality; artificial wetland utilizes the synergistic effect of plants, microorganisms and soil to naturally purify the wastewater, which is characterized by low investment, low operation cost and good ecological benefits. The artificial wetland utilizes plants, microorganisms and soil to purify wastewater naturally, which has the advantages of low investment, low operation cost and good ecological benefit.

Recycling of Waste Packaging Materials

A perfect recycling system should be established for the waste packaging materials. Palm oil mills can cooperate with professional recycling enterprises to collect and transport waste plastic drums and woven bags. The recovered packaging materials can be remade into new plastic products after cleaning, crushing, granulating and other processes to realize the recycling of resources. At the same time, strengthening the management of packaging materials and promoting the use of biodegradable and easy-to-recycle packaging materials are also effective measures to reduce the pollution of waste packaging materials.

The generation of palm oil mill wastes is unavoidable, but through scientific and reasonable treatment methods, these wastes can be transformed into valuable resources, realizing the recycling of resources and the sustainable development of the environment. The government, enterprises and all sectors of the society should work together to strengthen the supervision and investment in the treatment of palm oil mill wastes, to promote the development of palm oil industry in the direction of green and environmental protection, and to contribute to the protection of our home planet.

gao

Henan Zhongrui Grain is a high-tech enterprise specializing in the research, development, manufacture and sales of oil press equipment, and has been deeply engaged in the field of oil processing for more than ten years. The company integrates design, production and testing, and its products cover screw oil press, hydraulic oil press, automatic refining production line, etc., which are suitable for rapeseed, peanut, soybean, sesame and other oilseeds, and help customers to realize efficient, energy-saving and environmentally friendly oil and grease production.

Contact Us

Product Center

menu

Recommended

© 2025. All Rights Reserved. 豫ICP备19039166号 Theme By XinTheme