- We are a manufacturer of oil press equipment and grain and oil processing equipment.

- Email:2334065214@qq.com

In the palm oil industry chain, the quality of refining equipment directly determines the quality of oil and production efficiency. In the face of many equipment manufacturers in the market, how to screen out the partners with both technical strength and service guarantee? This article starts from the three core dimensions of equipment performance, manufacturing process and service network, and combines industry cases and data to provide practitioners with systematic decision-making reference.

First, technical strength: from process design to production efficiency hard core indicators

1. Advanced refining process

Quality manufacturers need to master the integration of physical refining and chemical refining technology. For example, the 200-ton production line of Henan Zhongrui Grain and Oil Machinery adopts the five-stage linkage process of “degumming – deacidification – decolorization – deodorization – winterization”, and through the vacuum deodorization tower and the molecular distillation technology, it can reduce the content of free fatty acid from 5% to less than 0.05%, while retaining the natural vitamin E and carotenoids in palm oil. The PLC control system equipped with the equipment can monitor more than 20 parameters in real time, such as temperature and pressure, to ensure the stability of the refining process.

2. Balance between equipment capacity and energy consumption

Taking the 60-ton palm fruit pressing and refining equipment of Zhongrui as an example, its single-day processing capacity can reach 1,440 tons, and its oil yield can be increased by 8%-12% compared with the traditional equipment. The equipment adopts double screw press and three-stage filtration system, and its energy consumption is controlled at ≤35 kWh per ton of palm fruit, which is 15% lower than the industry average. For small and medium-sized processing plants, its 10-ton equipment reduces the motor power from 45kW to 30kW by optimizing the transmission structure, which significantly reduces the operating cost.

Manufacturing Process: Double Guarantee of Material Selection and Quality Control

1. Material Standard of Core Components

High-quality equipment needs to use 304 stainless steel and high-strength alloy steel. For example, the screw assembly of Zhongrui equipment adopts 2Cr13 wear-resistant alloy steel, with a hardness of HRC58-62, which extends the service life by 3 times compared with ordinary carbon steel. The inner wall of the refining tower is specially polished, with roughness ≤ Ra0.4μm, which effectively prevents the grease from hanging and oxidizing.

2. Quality control system

The industry benchmark companies usually pass ISO9001 quality certification and CE safety certification. Take Guorui Grease as an example, its production line has to go through 12 factory inspections including 72 hours continuous load test and pressure burst test. Key components such as reducer and hydraulic pump station need to pass 100,000 times of fatigue test to ensure the stable operation of the equipment under high temperature and high humidity environment.

Service system: full-cycle support from pre-sales consulting to after-sales maintenance

1. Customized solution capability

Excellent manufacturers need to have the ability to design process flow. For example, Zhongrui can provide three kinds of configurations for different customers’ needs:

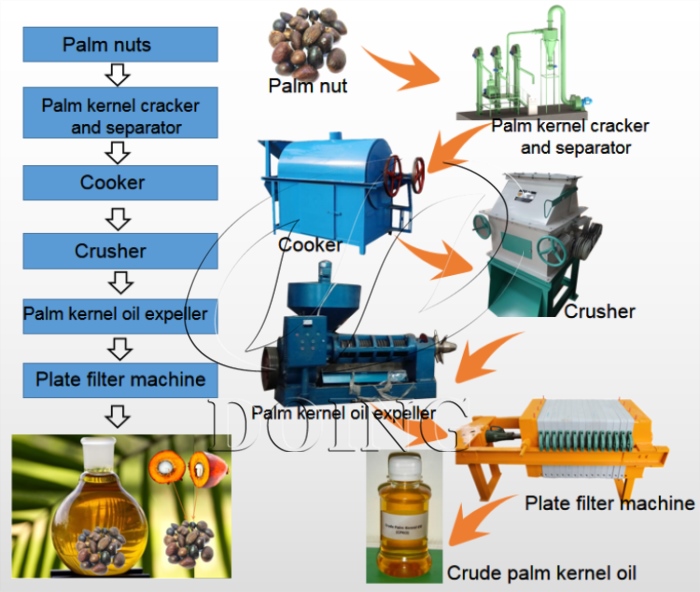

Basic version: single screw press + plate and frame filter, suitable for small workshops with daily processing capacity of ≤5 tons;

Standard version: double screw press line + degumming and deacidification system, to meet the needs of medium-sized factories with a daily processing capacity of 10-50 tons;

Flagship version: fully automated refinery line + palm kernel separation equipment, suitable for large-scale enterprises with a daily processing capacity of ≥100 tons.

2. After-sales service response mechanism

The leading companies in the industry usually establish the service standard of “4 hours response + 24 hours on-site”. Zhongrui has 12 service outlets nationwide, equipped with more than 30 professional engineers, which can provide one-stop services such as equipment installation and commissioning, operation training, and regular inspections. Its “equipment health file” system can track equipment operation data in real time and warn potential failures in advance.

Industry reputation and case verification

1. Customer case analysis

A large palm oil group in Southeast Asia: after adopting Sinoref’s 200-ton refining line, the acid value of the product was reduced from 0.8mgKOH/g to 0.1mgKOH/g, which meets the international standard for edible oil, and the annual production capacity was increased by 40%.

A small and medium-sized processing plant in Africa: after introducing Sinoref’s 10-ton equipment, the oil yield was increased from 18% to 23%, the labor cost was reduced by 60%, and the oil yield was reduced by 6% to 6%, and the labor cost was reduced by 60%. Labor cost was reduced by 60%, and the investment cost was recovered within 6 months.

2. Industry Evaluation and Certification

Sinovel has been selected as one of the “Top 10 Brands of Grain and Oil Machinery in China” for three consecutive years, and its equipments have passed the SGS test of the European Union and the MPOB certification of Malaysia. Customer satisfaction survey shows that its equipment failure rate ≤ 0.5%, after-sales service satisfaction of 98.6%.

Conclusion: Three golden rules for choosing manufacturers

Technology matching degree: give priority to enterprises with independent R&D capability and patented technology;

Service sustainability: examine the service provider’s network coverage, spare parts inventory and response speed;

Cost-benefit ratio: comprehensively evaluate the equipment procurement cost, energy consumption cost and maintenance cost.

Under the background of palm oil industry upgrading, choosing manufacturers with both technical strength and service guarantee is not only the key to guarantee production efficiency, but also an important strategy for enterprises to realize sustainable development.

gao

Henan Zhongrui Grain is a high-tech enterprise specializing in the research, development, manufacture and sales of oil press equipment, and has been deeply engaged in the field of oil processing for more than ten years. The company integrates design, production and testing, and its products cover screw oil press, hydraulic oil press, automatic refining production line, etc., which are suitable for rapeseed, peanut, soybean, sesame and other oilseeds, and help customers to realize efficient, energy-saving and environmentally friendly oil and grease production.

Contact Us

Product Center

menu

Recommended

© 2025. All Rights Reserved. 豫ICP备19039166号 Theme By XinTheme