- We are a manufacturer of oil press equipment and grain and oil processing equipment.

- Email:2334065214@qq.com

Palm oil, as the most consumed vegetable oil species in the world, the price of its processing equipment shows a significant gradient due to the capacity scale, technical configuration and brand differences. This paper combines the latest market data in 2025, from the type of equipment, technical parameters and industry trends in three dimensions, systematic analysis of the cost of palm oil processing equipment.

First, the capacity scale determines the price benchmark

Small home equipment

For individual farmers or family workshops, single screw palm oil presses have become the mainstream choice. Henan Guorui oil launched 300-500kg/h model, equipped with high-strength carbon steel body and intelligent temperature control system, priced at about 8,000-12,000 yuan / unit. This kind of equipment is easy to operate, but manual assistance is needed to complete the pre-treatment process such as fruit bunch de-fruiting, cooking and fermentation.

Small and medium-sized commercial equipment

1-5 tons/hour capacity double screw oil press has become the standard for small and medium-sized processing plants. Take Henan Dongying Environmental Capital’s 10 tons/hour fully automated production line for example, which includes fruit bunch crusher, cooking tank, double screw press and three-stage filtration system, priced at about 126,000-150,000 RMB/set. This line can realize continuous production from fresh fruit to gross oil, and the oil yield is 15%-20% higher than the traditional process.

Large industrial production line

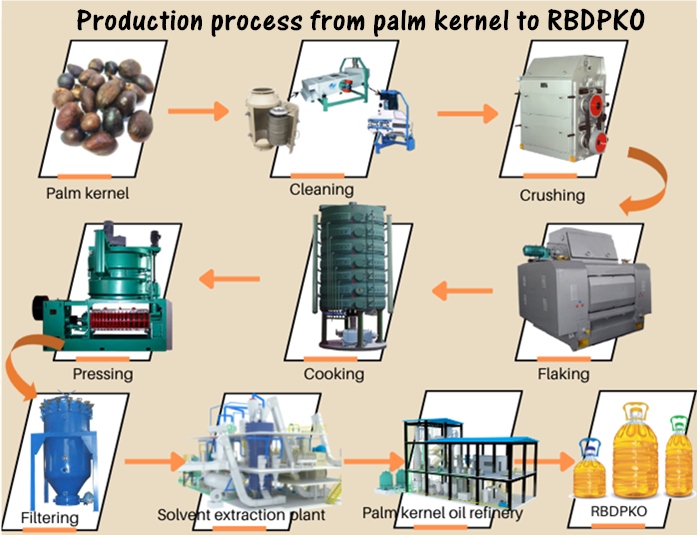

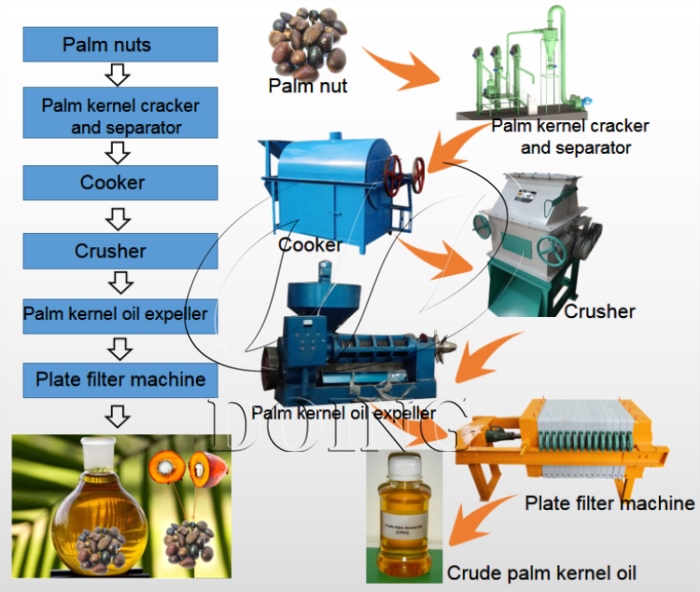

chemical leaching production line above 50 tons/day scale needs to integrate the four modules of fruit string pretreatment, pressing, solvent extraction and refining. Henan Huatai Cereals and Oils Machinery has launched 100 tons/day palm oil complete sets of equipment, adopting Germany Siemens PLC control system, priced at about 6.87-10 million yuan/set. This type of production line can produce RBD palm oil in line with EU standards, but need to support the construction of sewage treatment and exhaust gas treatment facilities.

Second, the technical configuration affects the price gradient

Basic equipment

Single machine equipment using mechanical pressing process, such as Hebei Huipin 260 automatic double screw oil press, priced at about 21,000 yuan / unit. This type of equipment can only produce gross oil, and requires the purchase of refining equipment for subsequent processing, which is suitable for startups with limited budgets.

Refining integrated equipment

Gongyi Wanlong Machinery’s 26,700,000 RMB/unit linseed oil palm oil refining machine integrates four processes of dephosphorization, deacidification, decolorization and deodorization, which can reduce the acid value of gross oil from 15mgKOH/g to less than 0.1mgKOH/g. This kind of equipment significantly improves the added value of the products, but it needs to be equipped with a steam boiler and a heat-conducting oil furnace.

Intelligent production line

Guorui Oil’s latest fully automated palm oil processing system, which realizes string maturity grading through AI visual inspection and adopts 5G IoT technology to monitor real-time operation status of the equipment, is priced 30%-50% higher than the traditional production line. The system can reduce labor costs by 40%, but requires a professional operation and maintenance team.

Third, industry trends and price fluctuations

Biodiesel demand driven

With the promotion of Indonesia’s B40 biodiesel policy, palm oil futures prices in 2025 showed a trend of “first half of the year, rebound in the second half of the year”. palm oil futures fell to 4,000 ringgit / ton in March, after June has risen to 4,350 ringgit / ton. Raw material price fluctuations directly affect the equipment procurement decisions, some companies choose to lock in the price trough equipment orders.

Accelerated technology iteration

Double screw pressing technology replaces traditional hydraulic pressing, increasing oil yield by 8%-12%; supercritical CO₂ extraction technology realizes palm kernel oil with zero solvent residue, but equipment cost increases by 200%. Technological innovation has shortened the equipment renewal cycle to 3-5 years.

Upgrade of environmental protection requirements

The newly revised Hygienic Code for the Production of Edible Vegetable Oil requires palm oil processing plants to be equipped with VOCs treatment devices and wastewater reuse systems. Henan Shuangxing Machinery introduced environmentally friendly palm oil processing equipment, through cyclone dust removal + activated carbon adsorption process, so that the exhaust emissions meet the standards, but the cost of equipment increased by 15% -20%.

Purchasing Suggestions

Capacity Matching Principle

It is recommended to determine the scale of equipment according to the formula of “daily processing capacity = raw material supply × 70%” to avoid idle capacity or overload operation.

Selection of technology route

Start-ups can give priority to modular equipment, such as Guorui Oil’s “pressing + refining” combination set, which can be used to expand production capacity as needed at a later stage; large-scale enterprises are advised to invest in a fully continuous production line in order to obtain economies of scale.

Supplier Qualification Verification

We focus on whether the enterprise has ISO9001 quality management system certification, EU CE safety certification and pressure vessel manufacturing license. Head enterprises such as Henan Dongying Environmental Capital and Guorui Oil & Grease, whose equipment failure rate is 40% lower than the industry average.

The current palm oil processing equipment market presents a competitive pattern of “high-end intelligence, mid-range modularity, low-end homogenization”. Purchasers need to combine their own financial strength, technical reserves and market positioning, to seek a balance between equipment performance, procurement costs and operational efficiency. As the demand for biodiesel continues to grow and environmental protection policies tighten, equipment with energy saving and clean production capacity will become the mainstream of the market.

gao

Henan Zhongrui Grain is a high-tech enterprise specializing in the research, development, manufacture and sales of oil press equipment, and has been deeply engaged in the field of oil processing for more than ten years. The company integrates design, production and testing, and its products cover screw oil press, hydraulic oil press, automatic refining production line, etc., which are suitable for rapeseed, peanut, soybean, sesame and other oilseeds, and help customers to realize efficient, energy-saving and environmentally friendly oil and grease production.

Contact Us

Product Center

menu

Recommended

© 2025. All Rights Reserved. 豫ICP备19039166号 Theme By XinTheme